Harvey’s Engineering, based in Bozeman, MT, is experiencing the benefits of automation firsthand. In this interview, Brian Nickel explains how the ability to quickly capture an accurate 3D point cloud eliminates errors and improves prefabrication processes for mechanical and plumbing, HVAC, hydronics and sheet metal – resulting in a high-productivity approach. Watch the interview to learn more.

Discover how Leica Geosystems’ iCON Total Station Solution enhances your MEP layout performance

Workflow in Action: MEP Sleeve Layout

Peer Insight: The Sack Company

Brandon Spainhour

BIM/CAD Coordinator

A full-service MEP contracting company that has been around the southeast since 1945, The Sack Company has used modeling and layout technology on an as-needed basis in the past. But a fairly recent project – a two-story elementary school near Savannah, Georgia – was the first in which everyone used the BIM process from start to finish.

The firm worked in coordination with the general contractor for the Isle of Hope Elementary School, using BIM to recreate 2D designs provided by architects and engineers in the 3D world. Not only did the BIM process allow them to perform clash detection and create more accurate estimations, they could also “check” their designs in a 3D environment, avoiding costly rework.

“If you let the technology do its job, it saves a lot of time and money,” said Brandon Spainhour, The Sack Company’s BIM/CAD coordinator. “We can visually capture any potential problem areas so that they can be redesigned before construction begins. It also allows us to build things offsite and ship them to the jobsite, which limits the need for storage and also saves time and money.”

Efficiency Goals

- More accurate and precise layout models

- Real-time BIM model access in an IFC format

- See model issues & inconsistencies in real-time – catch errors faster

- Generate valid point data that’s been checked/verified

- Comfortable technology adoption – leading to full technology use on next job site

Digital Layout Improves Accuracy, Efficiency

Shortly before the Isle of Hope school broke ground, The Sack Company purchased a Leica iCON robotic total station and iCON tablet. To try out the technology, they used it to backcheck what had already been laid out by hand with string and tape.

Once the work was checked with the total station, several errors were found that were fixed before the concrete slab was poured.

The Savannah school project was the first time the firm had used the equipment and BIM process from the beginning, primarily to verify underground work and floor penetrations.

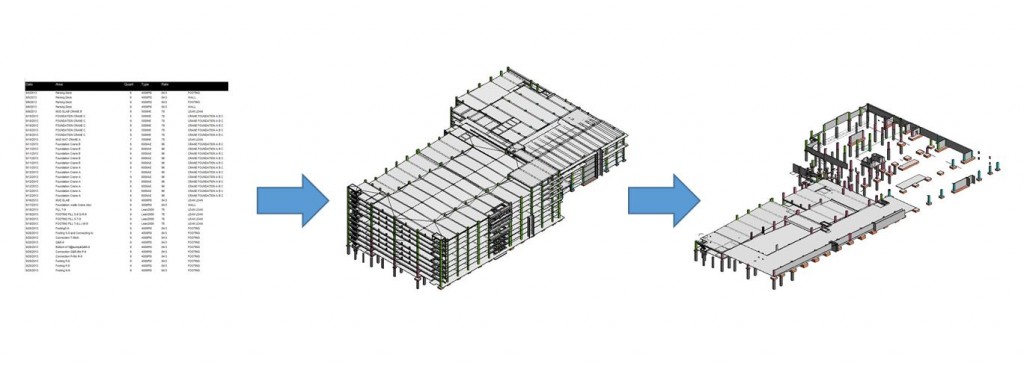

“Once we received the designs from the architects and engineers, I used the field software to input the points of interest that needed to be marked in the field,” said Spainhour. “We then exported that out to the field crews who laid out those areas.”

If clashes were found, Spainhour said, changes and adjustments were easily made in-house and e-mailed to the field crews, who uploaded the changes to a thumb drive that could then be transferred to the tablet. Early on, crews in the field – most still very new to the Leica total station – liked what they saw.

“It’s quicker and more efficient and doesn’t require as many people to use it,” said Spainhour. “We have one person dedicated to the total station and he does it all, from plumbing to electrical, so it doesn’t take away from crews doing their jobs.”

BIM Provides Savings, Reduces Risk

Spainhour said that as more and more general contractors are requiring subcontractors to work in BIM, having the technology and capabilities to build in a BIM environment will help the firm win jobs. That said, there was initially a little resistance from those in the field who had not yet had an opportunity to see the advantages of the technology.

“It’s more work upfront to follow a BIM process, and not all of our project managers and guys in the field have seen what the Leica system can do,” said Spainhour. “But at our quarterly meetings, those who have seen the benefits firsthand are raving. Word of mouth is spreading and that’s a good thing.”

The firm planned to use its new total station and tablet on its next project, a hotel expansion on Sea Island, Georgia. The tool would be used for underground plumbing and penetrations as each level of the building was put together.

“We probably won’t use BIM to its fullest extent on the hotel project because of the simple nature of the building itself – hotel rooms are very similar and don’t require as much coordination,” said Spainhour. “But for projects like schools – where we have seen architects creating fancier designs and there is limited space, duct work and tight fits – having everything in a 3D environment and using a BIM process to make sure it will work once it’s built is invaluable.”

Spainhour said the single biggest benefit is that it makes everyone’s job easier.

“Using the robotic total station tied together with a BIM process saves us time, money, and reduces overall project risks,” he said. “Being able to see things in a 3D environment makes it easier to understand what you are looking at so you can ask better questions. Rather than going through hundreds of pages of design documents, you can open a single model.”

iCON Solutions enhance your MEP layout performance with:

More from your peers: MEP Sleeve Layout

More INSIGHTS for MEP Layout

Rethink your MEP Work with ICON Solutions

Designed to maximize your formwork efficiency, iCON technology streamlines your concrete application by integrating your 3D design model from the office directly into the field workflow to produce accurate and verified point data in real-time – eliminating delays from BIM coordination and manual exporting & converting of files.

This intuitive, one-person solution empowers your limited crew to quickly tackle more work without sacrificing quality – enabling you to win and get to the next job faster.

Time to Rethink your MEP layout

Contact us now to find the solution for you!