The total stations you need to enhance your layout performance

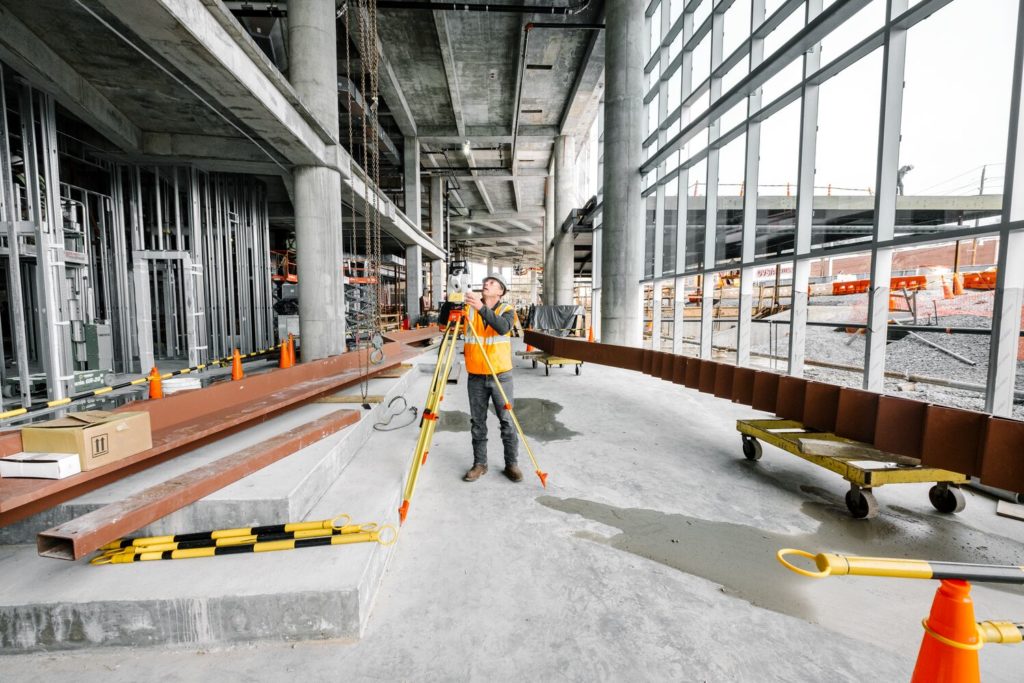

Designed to maximize efficiency in the field, Leica’s iCON total station technology streamlines your layout application by integrating your fully rendered 3D design model from the office directly into the field workflow to produce accurate and verified point data in real-time – eliminating delays from BIM coordination and manual exporting & converting of files.

Our intuitive, easy-to-use total stations are single-person operating, empowering your limited crew to quickly tackle more work without sacrificing quality – enabling you to win and get to the next job faster.

Robotic Total Stations

Leica iCR80

One-person total station guaranteeing layout efficiency with the most reliable, simple and automatic set up procedure, industry-leading prism lock, and flexible handling of fully rendered 3D design models in the field

Leica iCR70

Easy-to-use, one-person operating total station designed to accelerate construction and installation processes with flexible handling of fully rendered 3D design models in the field – helping you achieve more layout points all day, every day

Manual Total Stations

Leica iCB70

Efficient manual total station with either prism or reflector-less measurements and 4G mobile data capability for construction data transfers between the office and the instrument directly

Leica iCB50

Easy-to-use, manual total station is usable with minimal training and prepares & execute construction tasks faster, simpler and more accurately

Multistations & Layout Tools

Leica Nova MS60

The ultimate all-rounder, combining total station functionality with 3D laser scanning, GNSS connectivity and digital imaging into one instrument

Leica iCT30

Easy-to-use, high-performance construction layout tool designed for complex building construction layout applications

![]() “On one of our most recent projects, a 30,000 square foot building, we had a total of 1,027 points to set and one man, working with the robot, was able to do the work in two days. With our previous methods, that would have taken three days, with a two-man crew. Especially on large buildings, there’s a very clear return on investment.”

“On one of our most recent projects, a 30,000 square foot building, we had a total of 1,027 points to set and one man, working with the robot, was able to do the work in two days. With our previous methods, that would have taken three days, with a two-man crew. Especially on large buildings, there’s a very clear return on investment.”

VP of Concrete

Frazier Masonry Corporation

Rethink traditional layout methods with a 3D model-driven solution

The most efficient field-to-office solution for improved speed & layout accuracy

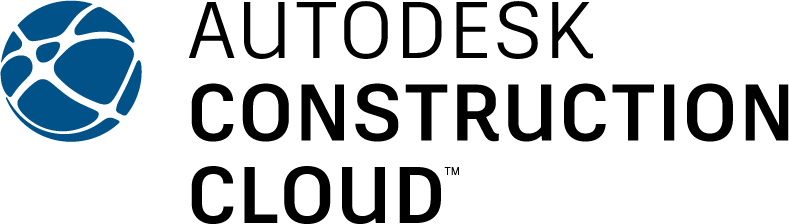

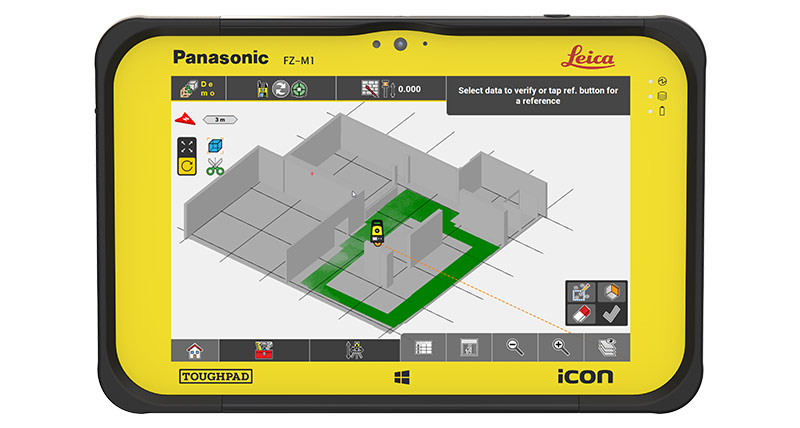

Leica iCON build construction software provides unseen versatility and flexibility for field crews to conduct layout, as-built and verification tasks on projects.

Leica iCON build has you covered no matter where in the building construction process. With smart digital workflows for site preparation, structures (concrete, wood, steel), MEP & HVAC, interiors and exteriors, field crews can layout with speed, performance and accuracy – improving quality, reducing errors & enhancing construction execution.

Increase performance and productivity on site with an innovative software design, smart digital workflows and an easy-to-understand interface. Layout more points per day and verify as-built data against design models to speed up project progress and minimize rework and future clash issues.

Easy-to-use interface

Simple to use and easy to master, iCON build enables field crews to put design data to work with a wide range of supported sensors. Using the same, interchangeable user interface results in less training, increased motivation and keeping your investment to a minimum.

Exceptional layout functionality

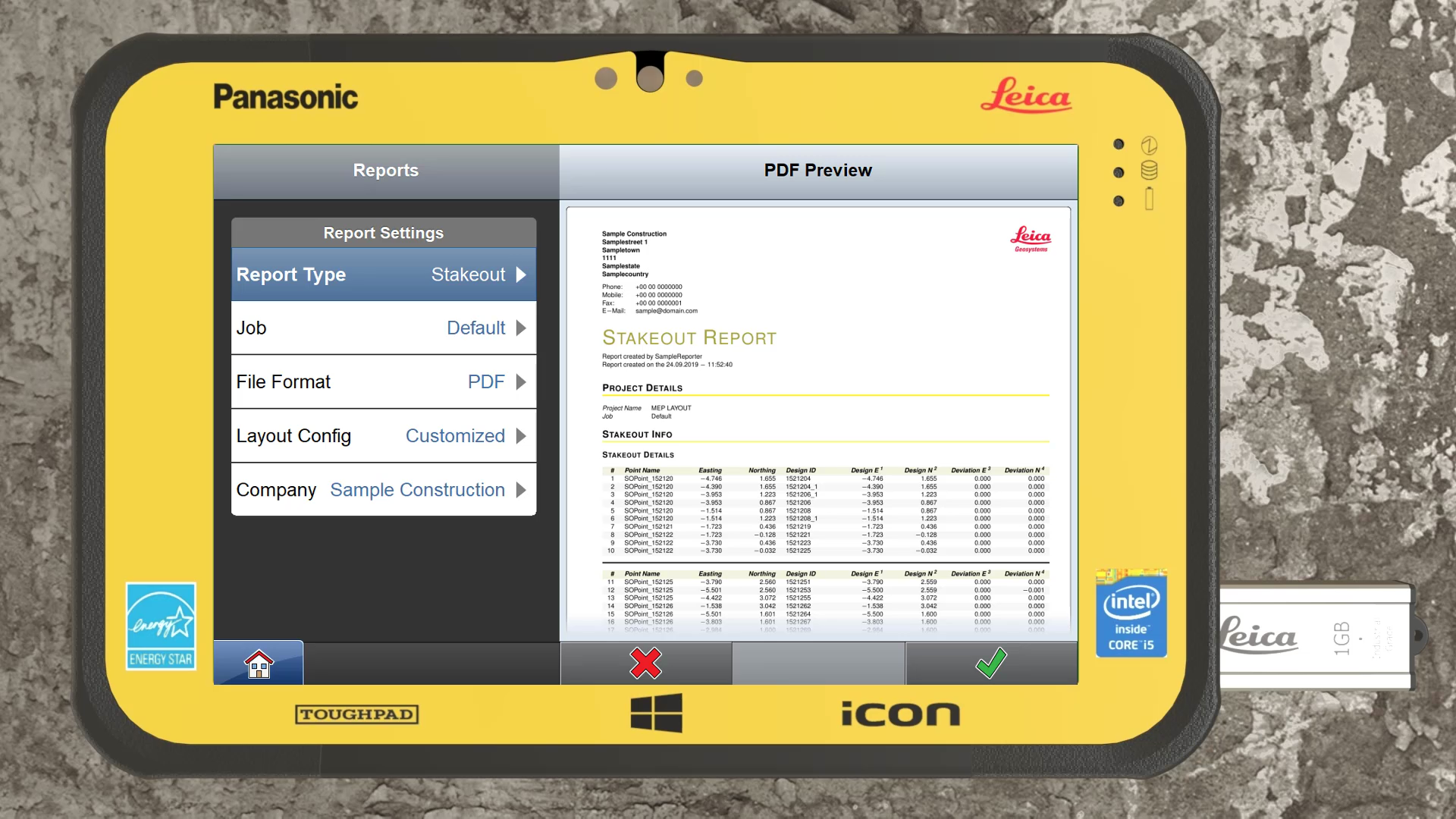

Connecting to construction cloud services means that field crews always have access to the most reliable design data and models. Laying out on site becomes a simplified process, while millimeter accurate field data and reports can be delivered seamlessly back to design teams for quick decision making and project progress tracking.

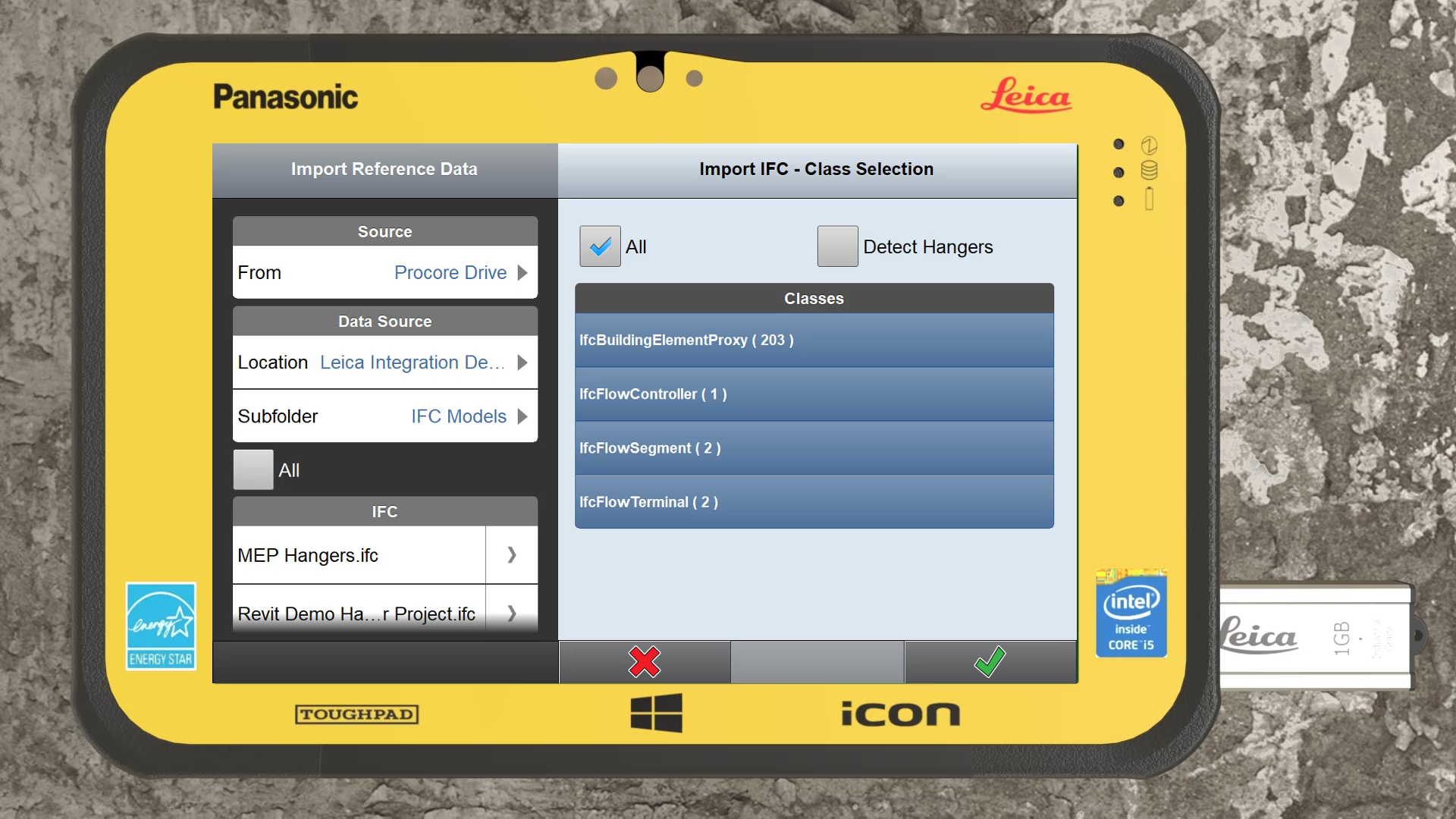

Import multiple files of different types including DGN format in a single workflow

Easily identify & select the desired objects to layout within the auto-split 50/50 IFC Tree View

iCON Field Software Simulator

Try out our iCON Field Software Simulator for free

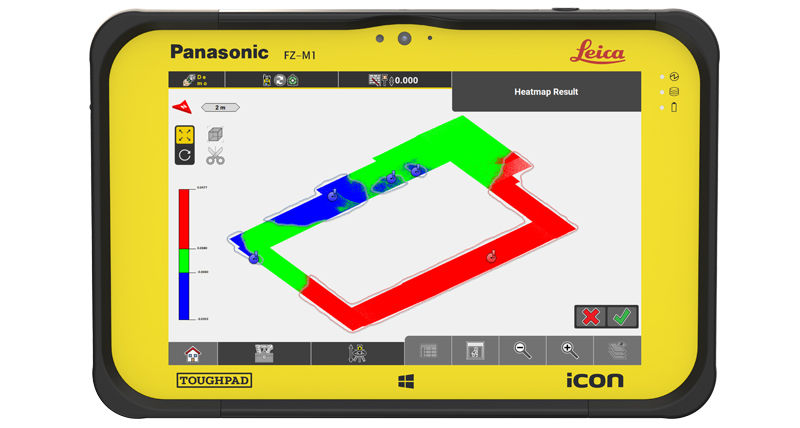

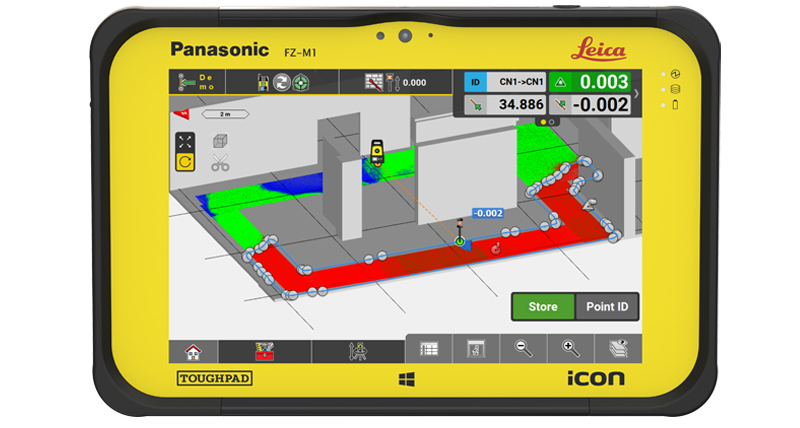

Enhance your BIM workflow with Real-Time Point Cloud Verification in Field

Using a 3-step process, the iCON field verification app allows contractors to extend their possibilities through the use of multiple integrated sensors, allowing for easier, more complete and real-time verification on site.

3-Step Workflow

1

Capture

2

Verify

3

Layout

Unlike other solutions that require the data to be transferred to the office, Leica iCON field software enables field crews to complete complex verification tasks in real-time, on site using single point measurements or point cloud data captured via total station.

With Leica iCON field software, field crews can complete all layout tasks and make infield verification decisions with a single solution – enabling better in-field decision making and faster corrective measures to keep projects on track.

Use Cases & Workflows

-

Analysis for dry/wet concrete pour

-

Slab scanning for surface flatness & analysis

-

Inspect columns, walls & formwork

-

Verification of pre-cast concrete walls before on-site delivery

-

Installation verification on-site

-

Structures verification, concrete, steel & wood

-

Pre-pour documentation, post-tension cable, box outs, sleeves

-

Exteriors & Facades systems

![]() “The very early return on investment on the equipment is being able to find conflicts within the drawings. If I find potential clashes that can impact cost and the schedule months in advance before our guys even get out there, it pays for itself. That in itself is worth the investment in the hardware and software.”

“The very early return on investment on the equipment is being able to find conflicts within the drawings. If I find potential clashes that can impact cost and the schedule months in advance before our guys even get out there, it pays for itself. That in itself is worth the investment in the hardware and software.”

BIM Manager

Facchina Construction

Integrated technology for a more streamlined BIM Layout workflow

iCON Solutions feature connectivity with leading industry software systems to offer construction professionals a more efficient building construction workflow – contributing to a more seamless, streamlined process and data transparency at the jobsite and in the office.

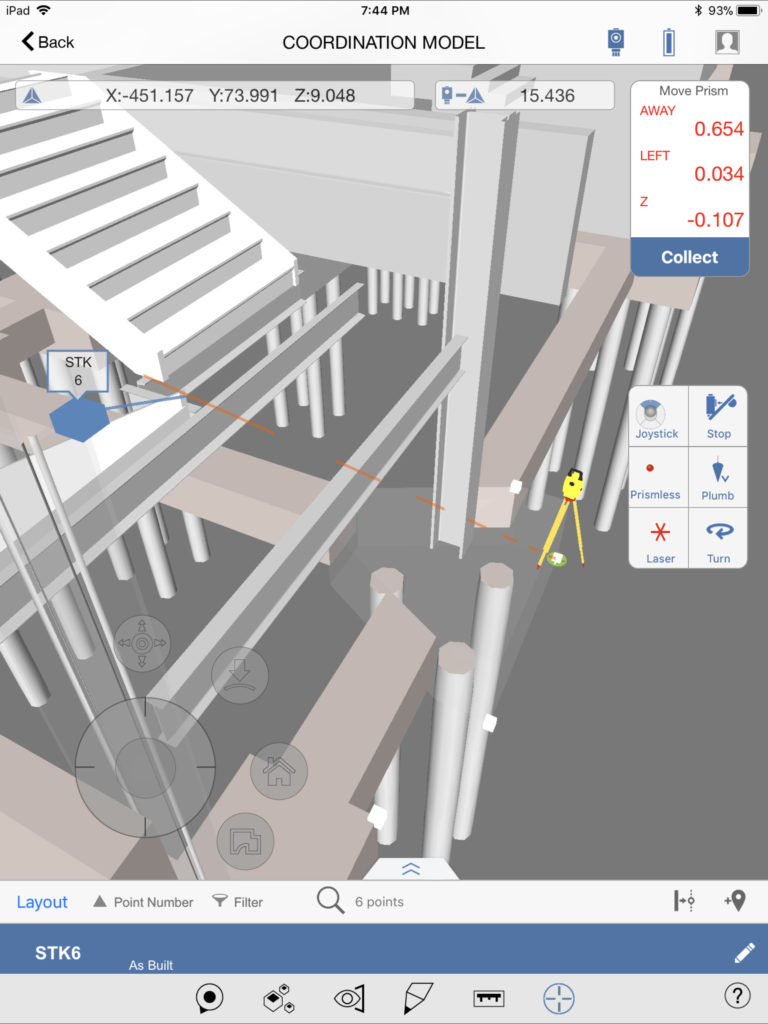

By connecting iCON field software with Autodesk BIM 360 Docs, a construction document management software enabling project members to share construction drawings, documents and models from a centralized platform, customers will be able to create seamless workflows between office and field.

The Autodesk BIM 360 Layout app for iOS/Android provides construction contractors the ability to connect the coordinated model to the field layout and verification process, helping to increase job site productivity while improving the accuracy of staked or installed building components.

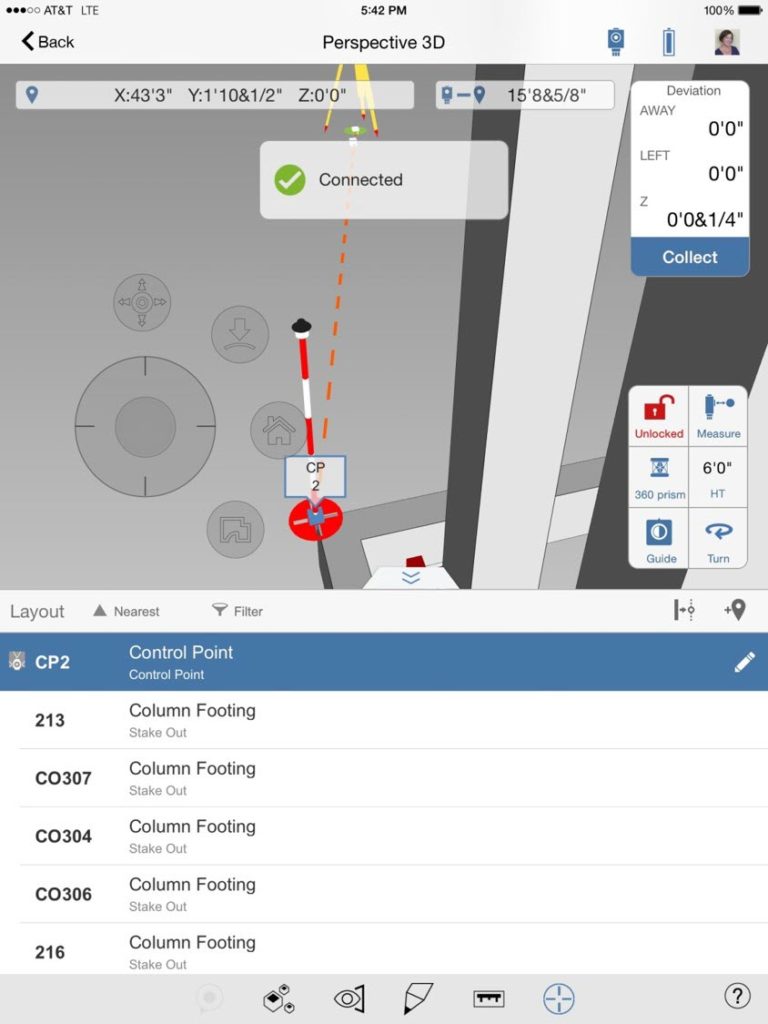

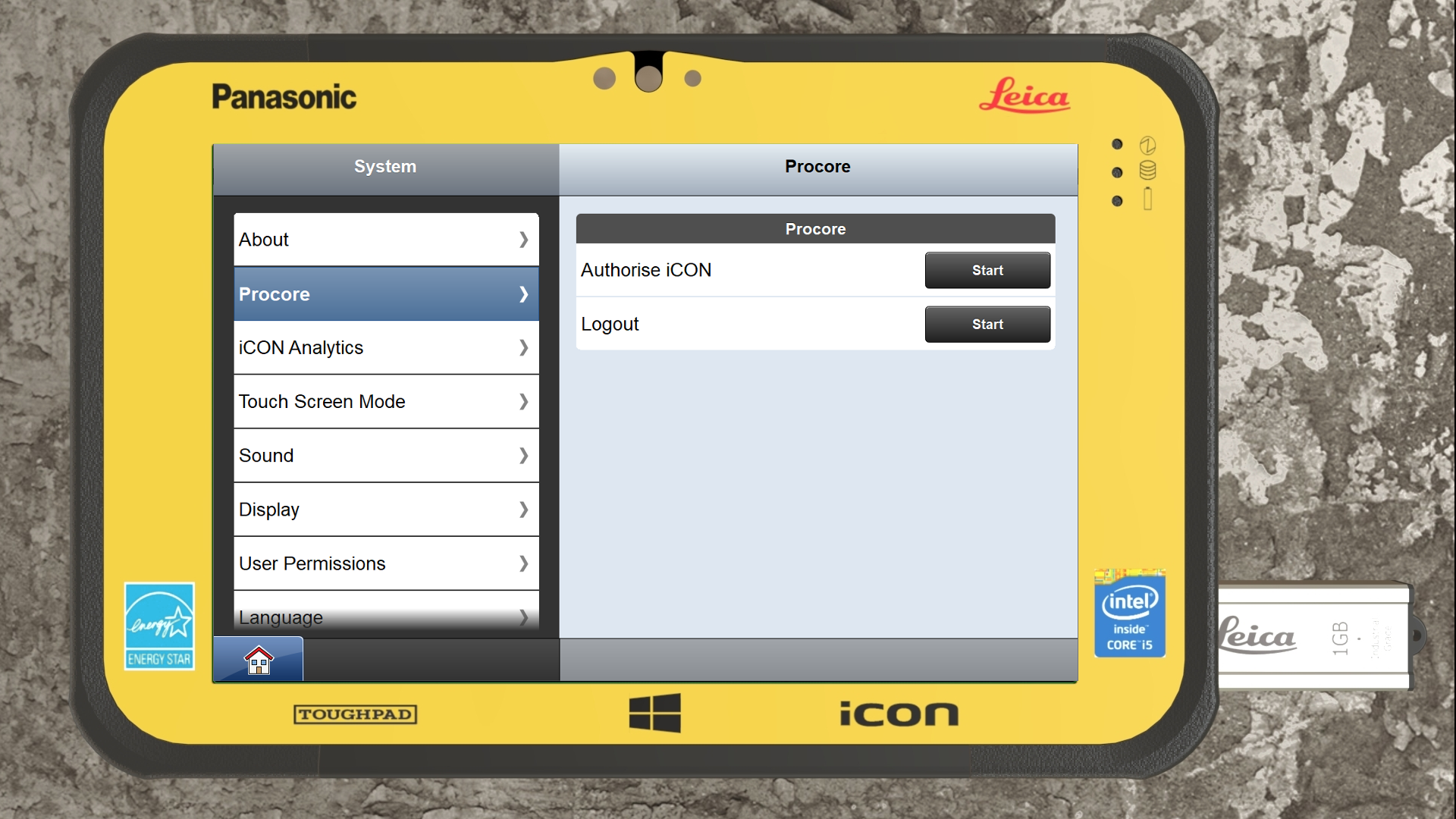

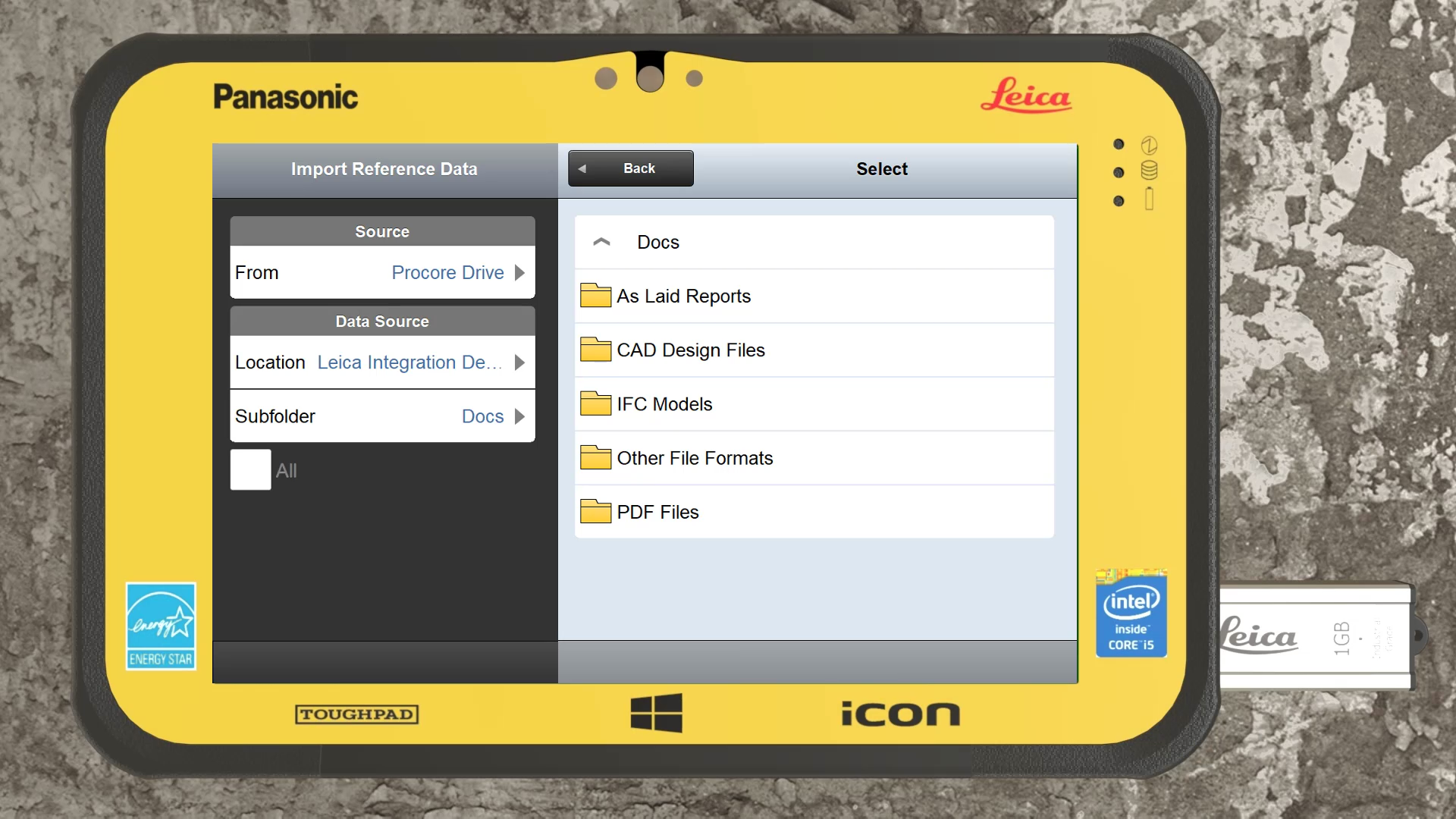

The collaboration with Procore Technologies Inc. results in a simplified data flow by giving the users the ability to exchange data between field and office.

A cloud connection between Leica iCON field and Procore’s construction management software allows all connected parties to communicate and document most up-to-date information. The workflow becomes smoother and thus reduces rework and saves time. Field crews can now connect directly on site to project data in the cloud, gaining access to previously inaccessible files. On the other hand, project managers in the office can now track progress of as-built and layout tasks based on true mm accurate field data.

Connect directly to Procore’s construction management solution for:

- Data exchange via cloud-based services between office and field

- Straightforward data flow to download the most reliable and up to date design data

- Direct reporting of as-laid and as-built information from the field to the office.

- Ability to utilize the Procore app on Windows 10 for further construction documentation

CUSTOMER INSIGHTS

![]() “Our survey costs are lower because we’re not onsite as long, and the risk of rework is practically eliminated because of our high accuracy. Plus, our ability to provide the layout in a timely and accurate way enables the trades to do their work and stay on schedule. We all win.”

“Our survey costs are lower because we’re not onsite as long, and the risk of rework is practically eliminated because of our high accuracy. Plus, our ability to provide the layout in a timely and accurate way enables the trades to do their work and stay on schedule. We all win.”

Head Surveyor

Clark Builders

Clark Builders’ Secret to Fast, Accurate Layout

How Digital Layout Drives Accuracy in Electrical Work for New Construction

Realizing the ROI of Digital Layout

BLOGS & ARTICLES

How to prevent costly re-work in building construction with in-field verification

Increasing efficiency in Building Construction with Leica iCON Robotic Total Stations

Start your digital construction journey with manual total stations

Three Reasons Contractors Prefer Leica iCON Construction Layout for BIM

Three Simple Tools for Digital Layout

Smart Digital Solutions for Building Construction

Why Leica Geosystems?

Leica Geosystems has been revolutionizing the world of measurement and survey for nearly 200 years. We provide powerful software, efficient workflows and experienced support for a complete construction technology solution.

With precise and accurate instruments, sophisticated software, and trusted services, Leica Geosystems delivers value every day to those shaping the future of our world.

Best Service & Support

VDC Manager

“We recently switched from another vendor due to Leica’s support and service after the sale. They are the best when it comes to that.”

Reliable Technology

VP of Operations

“Leica Geosystems stands on their reputation. Leica is all about their products & their reliability to do what they say they can do.”

Easy to Use

Senior Surveyor

“We needed a solution that was easy to adopt, user-friendly & required minimal onboarding time. Leica’s technology was easy to pick up & use straight away by the team”

Rethink how you work with iCON Digital Total Station Solutions

Contact us today to find the right solution for you!